|

|

Energy Efficient Upgrades

Business Start Up Guides

Energy Efficient Upgrades : Building Shell Improvements

Building shell improvements are one of the first places you should focus on when upgrading your existing facility. Start with the low cost/no cost opportunities. Like the lighting system, these factors are key to properly sizing the heating and cooling system during new construction or major upgrades.

These elements of the building are a major investment that should be purchased on a "life-cycle costing" or return-on-investment basis, rather than lowest initial cost. Over the life of the building, the operating savings in energy alone will far outweigh the initial cost of these items. Plus, in the case of new construction, it will be less costly to "do it right the first time," than to make even more costly upgrades to insulation, windows, walls or roofing material later.

The sections below will help you learn how to make your facility more energy efficient through improvements to your building shell. For additional information that may be applicable to your small commercial facility please visit ENERGY STAR Home Sealing.

Insulation

Insulation is a critical component of every facility, helping to keep you cool in the summer and warm in the winter. Always insulate your new facility to model building codes, which are discussed in the New Building Design section of this Guide. For retrofits, use these codes as guidelines to ensure that you get the amount of insulation that will save you energy and be cost effective.

Project Suggestion

To determine the correct amount of insulation for your project consult the following:

- Local energy codes and officials

- State energy offices

- Model energy codes such as the International Energy Conservation Code and those published by ASHRAE.

- DOE's Insulation Fact Sheet

- Flex Your Power's Commercial Product Guide Insulation

- National Insulation Association

- American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE)

Roofing

Energy-savings opportunities can be achieved by carefully choosing roofing materials and by purchasing ENERGY STAR qualified roof products when possible. Some areas that should be considered when upgrading your roof include:

- Insulation: When specifying or replacing a roof, insulation can be placed under the roof.

- Radiant Barriers: In addition to traditional insulation, radiant barriers save energy both in the summer and winter by re-directing radiant energy in the facility.

- Cool Roofing: These systems lower heat gain for facilities by reflecting the sun's radiant energy, saving energy on air-conditioning. Consult your roofing and HVAC professionals to learn if cool roofing is an option for your facility.

To learn more about energy-efficiency opportunities for roofing visit:

- ENERGY STAR Qualified Roof Products

- Lawrence Berkeley National Laboratory's Cool Roofing Materials Database

Walls

Exterior walls (and those connected to unconditioned spaces) should be insulated. When exterior walls are being constructed or are bare during a renovation, consider a quality building wrap. These materials have a low cost per square foot of material and can help drastically reduce air and moisture infiltration into the conditioned space.

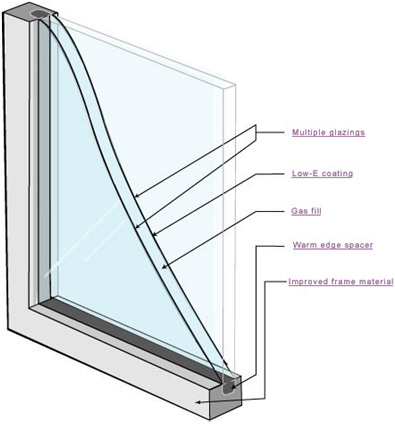

Windows

A single-paned window has an R-value (measure of the ability to prevent heat flow) of 1, making it little more than a hole in the wall. Fortunately, in recent years, double-paned windows, along with other energy-efficient features, have become more standard. Older facilities can likely benefit from improvements to windows. Improvements you should consider when upgrading your windows and frames include:

- Purchase ENERGY STAR qualified windows, which feature a combination of new technologies that save you energy and money

- Double or triple-paned glass

- Inert gas (e.g., krypton, argon, or nitrogen) fill

- Low-emissivity, advertised as Low-E, glass/film or other advanced coatings/films

- Window tinting appropriate for your region and facility orientation

- Insulated frames, low-conductivity materials

Many vendors are now promoting the advantages of window films - ranging from simple tints that block incoming light, to films that provide performance similar to Low-E glass, and advanced coatings that block specific wavelengths of light.

To learn more about windows visit:

- ENERGY STAR's Qualified Residential Windows, Doors, and Skylights

- DOE EERE's Consumer's: Guide Windows

Slabs and Foundations

Slabs and foundations are frequently overlooked areas where energy savings can be realized. Just like walls and roofs, there are insulation opportunities for these areas that will save you money. For new facilities, you should consider a vapor retarder between the foundation and the slab or earth. Vapor retarders reduce the amount of moisture, and other potentially harmful vapors, that can pass through slabs and foundations and add to discomfort and indoor air-quality issues in your facility.

Tightening An Existing Building

There are many low-cost/do-it-yourself actions you can take to help your facility reduce air leakage and costs. These actions include:

- Filling gaps around doors and window frames with caulk, spray foam, and insulative batting.

- Checking window and door weather stripping. If weather stripping is missing, hard, or cracked replace it.

- For exterior doors with a gap underneath, (e.g., if you can see daylight) install door sweeps.

Passive Solar Design and Orientation

The orientation of a facility can affect energy consumption, particularly the energy used for heating and cooling. For a new facility, consider passive solar design, or the practice of positioning a facility to take advantage of the sun's natural heating and light energy, and to shade a facility from the sun where desirable.

Energy Efficient Upgrades : Lighting

Did You Know?

Upgraded lighting can save money through reduced energy use, and result in increased occupant comfort and sales.

Lighting is a critical component of every small business. Employees must be able to see to perform their jobs, and objects and spaces must be aesthetically pleasing to encourage sales.

Depending on the type of business you operate, lighting accounts for 20% to 50% of electricity consumption. This means that significant cost savings can be achieved with energy-efficiency improvements, and due to continually improving equipment, lighting usually provides the highest return-on-investment of major upgrades.

The Formula for Lighting Energy Efficiency

Lighting TechnologyMake the decision early in your project to select energy-efficient lighting technology. The following pages discuss lighting technologies, their efficiency, and what might be right for your facility.

|

Lighting DesignHigh-quality lighting design includes the coordinated selection of lighting, fixtures, fixture placement, room finishes (e.g., high-reflectivity paint) to result in improved lighting quality. To achieve the best quality and efficiency from any new lighting system you install, consult a lighting professional with experience in energy efficiency |

Incandescent Lighting Technology

Thomas Edison invented the first commercialized electric lighting technology in 1879, the incandescent lamp. This simple, yet inefficient, technology has dominated lighting applications ever since. Incandescent lamps come in two common type varieties:

Did You Know?

An incandescent lamp is a better heater than a light, with nearly 90% of the input energy being converted and lost in waste heat.

- Standard Incandescent Lamps: Inefficient lamps used in many applications throughout a facility.

- Halogen Lamps: Halogen Lamps are a more advanced incandescent lamp technology commonly used to highlight merchandise and architectural features due to their white light and "sparkle".

Where can you find incandescent lamps in your facility?

|

|

Compact Fluorescent Lamps (CFLs)

CFLs are fluorescent lamps that have been specifically made in a compact form to replace incandescent lamps in traditional screw-in fixtures. These energy-efficient lamps come in a variety of styles and sizes and are suitable for a variety of applications. ENERGY STAR qualified CFLs use 75% less energy than a standard incandescent bulb and last up to 10 times longer. Replacing a 100-watt incandescent with a 32-watt CFL can save approximately $30 in energy costs over the life of the bulb.

The long life of CFLs makes them ideal to use in hard-to-reach places due to their reduced need to be replaced as often. In addition, CFLs are cool to the touch, making them safer than incandescent and halogen lamps. To learn more about CFLs visit:

- ENERGY STAR Qualified Compact Fluorescent Light Bulbs

- DOE EERE Consumer's Guide: Compact Fluorescent Lamps

- National Lighting Product Information Program's Screwbase Compact Fluorescent Lamp Products Report

Improved Halogen Systems

Did You Know?

Compact fluorescent lamps come in a wide variety of shapes and sizes to accommodate most applications, even models that resemble incandescent lamps.

Many incandescent lamps can be replaced with halogen lamps for a gain in efficiency and service life. Many standard halogens (aside from some specialty applications) can be replaced with high performance "Infrared" (IR) halogen lamps. These lamps work by increasing the operating temperature of the halogen lamp, increasing efficiency. Though more efficient than other incandescent and halogen lamps, these lamps are still inferior in efficiency to fluorescent and HID lighting systems.

Fluorescent Lighting

Fluorescent lighting is the "standard" technology for lighting spaces such as offices and classrooms, and is up to four times more efficient than the incandescent lamp. However, older, obsolete fluorescent lighting systems can result in poor light quality and flicker. Advancements in fluorescent lighting systems have resulted in the introduction of new systems that provide improved energy efficiency, lighting quality, and design flexibility.

The primary components of standard fluorescent lighting systems are the ballast, which modifies incoming voltage and controls electrical current, and the lamp (bulb or tube), the source of artificial light.

Did You Know?

Magnetic ballast fluorescent lighting systems are vintage technology dating back to 1939.

Traditional Systems:

- T12 Fluorescent Lamps: One of the most common, but least efficient fluorescent systems. T12 lamps can be identified by their 1.5-inch diameter.

- Magnetic Ballasts: Magnetic ballasts are common and still used extensively today due to their low initial cost. However, these ballasts are considerably less efficient than new electronic ballast designs and are prone to flicker and humming (particularly as they age).

Standard fluorescent lamps are commonly used in a variety of places in a facility. Some common applications include:

|

|

What energy-efficient technologies can replace T12 fluorescent lighting system?

Energy-Efficient Fluorescent Lighting Systems: These systems, using T8 (1" in diameter) and T5 (5/8" in diameter) lamps, offer improved efficiency, higher intensity, and potentially longer life due to reduced degradation in light output over time. T8 and T5 lighting systems are constantly increasing in flexibility and are now applicable to a variety of task and accent lighting applications, as well as general lighting of larger spaces. To learn more about T8 and T5 lamps visit:

- ENERGY STAR Qualified Products

- National Lighting Product Information Program: "Lighting Answers: T8 Fluorescent Lamps" Fact Sheet

- National Lighting Product Information Program: Lighting Answers: T5 Fluorescent Systems

Project Suggestion

You may be able to "de-lamp" or remove some of the lamps in your system and still have acceptable light levels, especially in concert with a T8 retrofit. Consult your lighting professional to see if this is an option for your facility.

Energy-Efficient Electronic Ballasts: When specifying a fluorescent lighting system, always specify electronic ballasts. These ballasts provide near flicker-free operation while using up to 30% less energy than magnetic ballasts.

To learn more about electronic ballasts visit:

- ENERGY STAR Qualified Products

- National Lighting Product Information Program: "Electronic Ballasts" Fact Sheet

- National Lighting Product Information Program: "Guide to Specifying High-Frequency Electronic Ballasts"

High-Intensity Discharge (HID) Lighting Systems

Due to their intensity, HID lighting systems are useful for lighting large areas from high ceilings, and range from 50 to 2,000 watts each. Older HID installations are often mercury vapor lamps, an extremely inefficient design. Like fluorescent lamps, HID systems have ballasts, and systems built before 1978 may contain potentially harmful substances such as PCBs (Polychlorinated biphenyls).

Project Suggestion

Consult your lighting professional about specifying more energy efficient T5 lighting systems instead of HID lighting systems.

HID lamps are commonly used in the following applications:

- Garages

- Warehouses

- Areas with high ceilings

- Exterior safety and security lighting

- Accent lighting

What HID technologies are most efficient for my facility?

For high-ceiling and exterior applications, specify metal halide or high-pressure sodium vapor lamps. In areas you wish to highlight, or accent particular merchandise, use small metal halide spotlights. To learn about HID lighting systems:

- National Lighting Product Information Program Lighting Answers: Mid-Wattage Metal Halide Lamps

- National Lighting Product Information Program: "HID Accent Lighting Systems" Report

In some cases, you may be able to reduce the wattage of your already installed HID lamps by purchasing and installing specially designed reduced wattage metal halide lamps. For example, a special 360-watt metal halide can replace a 400-watt metal halide. Consult your lighting professional for more information.

Exit Signs

Exit signs are an excellent, low-cost, low-labor opportunity to increase the energy efficiency and safety of your facility. Replacing incandescent exit signs that operate at about 40 watts per sign, or fluorescent exit signs that operate between 12 and 20 watts per sign, with an ENERGY STAR qualified exit sign can increase the energy efficiency of your exit signs by 3 to 8 times!

Did You Know?

ENERGY STAR qualified exit signs use 3 to 8 times less energy than incandescent and fluorescent illuminated exit signs and reduce maintenance.

Many ENERGY STAR qualified exit signs are based on light-emitting diode (LED) technology, while others are based on photoluminescent and electroluminescent technology. You may also be able to retrofit your exit sign with LED technology while retaining the housing. To learn more about ENERGY STAR qualified and other energy-efficient exit sign technologies please visit:

- ENERGY STAR Qualified Exit Signs

- ENERGY STAR LED Exit Sign Fact Sheet

(194KB)

(194KB) - National Lighting Product Information Program: "Exit Signs" Report

Fixtures

Specifying an energy-efficient lighting technology, such as T8 or T5 fluorescent lamps and electronic ballasts, is a critical step to improving the energy efficiency of your facility and saving money. However, lighting is a system and depends on the quality of the fixture (the apparatus that contain the lamp), combined with the lamp, ballast and placement (the position of fixtures in a room, which affects the amount of usable light that is supplied).

Fixtures come in a wide variety of applications. Fixture selection may be guided by:

|

|

Lighting Controls

Did You Know?

The most efficient light is the light not used. Many control technologies are available to save money and add convenience to your lighting system.

Controls are a key part of any lighting system. Specify controls that maximize the flexibility of your system while eliminating light usage, often automatically. Common controls include:

- Bi-level Switching: Control of a lighting system in groups of fixtures or lamps, for example bi-level switching allows you to turn-half of the lights in a room off when full illumination is not required. Bi-level switching is commonly used in offices, conference rooms, and classrooms.

- Dimmers: Dimming lighting systems allow you to control the amount of light and save energy. Dimmers are available for fluorescent and incandescent systems. Daylight dimmers are special sensors that automatically dim room lights based on the amount of free and natural daylight available. Dimmers are commonly used in conference rooms, classrooms, restaurants, and libraries.

- Occupancy Sensors: These sensors detect the motion of room occupants, turning off lights in unoccupied areas and turning them back on when movement is detected. Occupancy sensors are commonly used in restrooms, classrooms, and warehouses.

- Daylight Sensor (Photocells): A common inefficiency of exterior lighting systems is a tendency to "dayburn." This is when lights are on during the day, wasting energy and money. This problem can be prevented by installing light-sensitive controls that turn the lights on and off automatically based on daylight, thus producing convenient energy savings. Timers can be used, but do not react to changing daylight conditions.

To learn more about lighting controls systems visit:

- DOE Building Technologies Program: Lighting Controls

- National Lighting Product Information Program: "Occupancy Sensors" Report

- National Lighting Product Information Program: "Photosensors" Report

- Lighting Controls Association

- Energy Design Resources: "Design Brief: Lighting Controls" Fact Sheet

Daylighting

Did You Know?

Research has shown that daylighting not only saves money but also improves employee productivity and product sales.

Save money by harvesting the free light of the sun! Daylight can be harvested by simply not blocking windows, and by dimming/turning off the lights based on available daylight throughout your facility. Common daylighting strategies include:

- Controlling window light through blinds

- Sky lights and "sun tubes"

- Light shelves

- Daylight dimming systems

To learn more about daylighting visit:

- Daylighting Collaborative

- DOE Building Technologies Program: Daylighting

- Energy Design Resources Design Guidelines: Daylighting Guidelines

Future Lighting System Technologies

LED Lighting

In the last 20 years, light-emitting diode (LED) lamps have advanced from being indicators on consumer electronics, to an increasingly versatile and efficient lighting source. LED lighting has the potential to provide high efficiency, durability, and extremely long life. Currently, LED lighting is largely restricted to specialty uses such as accent lighting, LCD monitor backlighting, exit signs as well as use in traffic signals, vehicle brake lights, and strings of colored holiday lights. However, as the technology becomes more accepted in the market, its uses will expand and costs will become more competitive. A specific kind of LED, the organic light-emitting diode (OLED) promises to make energy efficient and designable light panels that can be used in a wide variety of architectural applications. To learn more about LED technology please visit:

- Solid State Lighting at the Lighting Research Center

- LED Center

- DOE Building Technologies Program: Solid State Lighting

Induction or Electrodeless Fluorescent Lamps

An induction lamp is a fluorescent lamp design that eliminates the most failure prone component of the system, the electrode, and produces light by exciting the lamp's gas fill with radio frequencies. The result is improved efficiency over conventional fluorescent designs and extremely long life (upwards of 50,000 hours). Several induction designs are already on the market, but these lamps are best used for applications where extremely long lamp life is desired due to maintenance issues. To learn more about induction lamps visit GE's Consumer and Industrial Lighting Induction Lamps.

Efficient Lighting Technology Selection Design Guide

Project Suggestion

When selecting a lighting consultant/designer consider selecting one who is certified "LC" by the National Council on Qualifications for the Lighting Professions or "CLC" by the American Lighting Association.

Many simple upgrades can be made with reasonable results to existing systems and standard specifications. Examples of these include:

- Substituting T8 fluorescent lamps and electronic ballasts for T12 lamps and magnetic ballasts.

- Replacing incandescent lamps with compact fluorescent lamps.

- Installing fluorescent lighting systems in place of incandescent lighting systems.

- Installing metal halide or high-pressure sodium vapor lamps in place of mercury vapor lamps.

Note: This table is for informational purposes only. Always consult your lighting professional before specifying a technology for your facility.

Energy Efficient Upgrades : Commercial Food Service Equipment

When you think of commercial food service equipment (CFSE), you probably think of restaurants, however CFSE is present in a variety of other facilities as well.

Facilities where CFSE may be found include:

- Restaurants

- Grocery stores

- Convenience stores

- Community centers

- Public assembly, sports and entertainment facilities

- Schools

- Congregations

If you operate a facility that serves food, there may be opportunities for saving energy and money from efficient CFSE equipment. CFSE is often the source of considerable energy and water consumption in a facility. ENERGY STAR has developed qualifications that identify some of the most efficient commercial food service equipment. ENERGY STAR qualified CFSE includes gas and electric deep fryers, hot food holding cabinets, gas and electric steam cookers, and commercial solid door refrigerators and freezers.

ENERGY STAR has developed a Commercial Food Service Equipment Incentive Finder. This tool provides information about rebates for ENERGY STAR qualified CFSE that are available from utilities and other energy-efficiency program sponsors.

Energy Efficient Upgrades : HVAC Systems

Proper heating, ventilating, and air-conditioning (known in the trade as HVAC) are key to maintaining a comfortable, healthy and productive work environment. Collectively, these systems account for approximately 40% of the electricity used in commercial buildings. Improved heating and cooling performance along with substantial energy savings can be achieved by implementing energy-efficiency measures.

Whether you wish to improve the efficiency of your existing heating and cooling systems or are considering upgrading to a new system, the information on this page will help you to make informed decisions!

Cooling and Heating Load Reduction

One of the first steps you should consider in your facility before upgrading your heating and cooling system is to reduce your load (i.e. how much heating and cooling you actually use). Reducing your facility's load allows existing systems to operate less frequently and newer systems to be designed smaller, thereby lowering operating costs. Common load reduction strategies include:

- "Tightening" your building shell and adding additional insulation to reduce leakage.

- Installing energy-efficient windows such as ENERGY STAR qualified windows.

- Upgrading lighting systems. Energy-efficient lighting systems emit less heat into conditioned space than older inefficient technology.

- Reducing solar gain (e.g., cool roofing and window tints) in cooling dominated climates, and in cold climates taking steps to increase solar gain.

- Selecting efficient office equipment and consumer electronics to reduce heat output.

- Controlling ventilation to improve occupant comfort and save energy.

Once you have addressed these areas, you can then make the most of your heating and cooling equipment dollars.

Heating and Cooling Systems

Heating and cooling systems are critical to most businesses, but also represent a large component of many facilities' utility expenses. Cooling systems, in particular, are typically very energy intensive and are almost always fueled by electricity. Their operation typically coincides with periods that are subject to peak and time of use charges.

Heating and cooling systems have advanced significantly in design and efficiency. For example, today's air conditioners use 30% to 50% less energy to produce the same amount of cooling as air conditioners made in the mid 1970s. Even if your air conditioner is only 10 years old, you may save 20% on your cooling energy costs by replacing it with a newer, more efficient model.

Heating and Cooling System Tips:

Project Suggestion

For commercial facilities, request an ACCA Manual N, and for home businesses request a Manual J, evaluation of your facility's heating and cooling loads before purchasing any major heating or cooling system. By following these guidelines you will receive a system that is sized appropriately for your facility.

- Consider implementing efforts to reduce heating and cooling load before selecting equipment.

- NEVER OVERSIZE! Avoid over sizing equipment at all costs. Over sizing equipment increases the capital cost at the time of the installation and the costs of operation of the equipment. Request that your HVAC professional conduct an Air Conditioning Contractors of America's (ACCA) Manual N Commercial Load Calculation to ensure proper sizing.

- When selecting a new cooling system, have your HVAC professional provide you a quote and specifications for a standard-efficiency and high-efficiency unit including lifecycle costs. If the lifecycle cost is less on the high-efficiency unit, purchase it.

- When purchasing Room Air Conditioners or Light Commercial heating and cooling units, select those units that are ENERGY STAR qualified.

- Consider energy recovery ventilation systems to reclaim waste energy from the exhaust air stream and use it to condition the incoming fresh air.

- In humid climates, consult your HVAC professional about supplemental dehumidification. By controlling humidity at your facility, you can increase occupant comfort and allow for further downsizing of equipment.

- Consider specifying economizers. Often available at a low incremental cost, these units draw in fresh air from the outside when the temperature outside is lower than the temperature inside.

- Install programmable thermostats and use automated settings to achieve savings.

- At a minimum, specify National Electrical Manufacturers Association (NEMA) premium motors on HVAC equipment, and consider specifying variable speed drives (VSD) on condenser and evaporator fans.

- In dry climates, consider evaporative coolers. These coolers use the evaporation of water to cool spaces, eliminating the need for energy intensive compressors.

- For facilities that have heat-generating processes such as cooking, or onsite distributed generation equipment, consider heat recovery as a way to capture free waste heat and use it to offset facility heating and cooling costs.

- For areas such as warehouses and garages, consider installing radiant heating . Radiant heating warms objects instead of the air, and requires less fuel. Radiant heat is also useful for warming exterior areas that require heating, such as patios and waiting areas.

- Many buildings are impacted by what goes on inside the building just as much as (and sometimes even more than) the weather conditions outside. That is why it is important to properly size equipment and consider the use of a demand controlled ventilation system

coupled with economizers to meet the internal loads of the building, e.g., commercial kitchens, computer data centers, etc.

coupled with economizers to meet the internal loads of the building, e.g., commercial kitchens, computer data centers, etc.

Heating and Cooling System Energy-Efficiency Resources

- ENERGY STAR Qualified Products: Heating & Cooling Efficiently

- EPA Indoor Air Quality (IAQ) Resources

- DOE EERE Consumer's Guide: Space Heating and Cooling

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE)

- Air Conditioning Contractors of America Resources

- FEMP Energy-Efficient Products: How to Buy an Energy-Efficient Commercial Unitary Air Conditioner

- Consortium for Energy Efficiency: High-Efficiency Commercial Air Conditioning & Heat Pumps

- Flex Your Power's Heating, Ventilation and Air Conditioning (HVAC) Systems

Control Systems

A great way to improve the efficiency of heating and cooling systems is to incorporate control strategies that ensure systems are used only when necessary. Common control strategies include ENERGY STAR qualified programmable thermostats, multiple zones, and CO2 demand sensors. These strategies can be specified on new heating and cooling systems and retrofitted to older systems as well.

- ENERGY STAR Qualified Programmable Thermostats: These simple, easy to install thermostats allow convenient night/weekend setback to save you money. Models range from $50 to $200 depending on the desired features and usually include manual overrides to ensure comfort for late night workers.

- Multiple Zones: By dividing your facility up into multiple heating and cooling zones, your system can deliver more efficient heating and cooling by eliminating inaccuracies from a central sensor point. In addition, building occupants in different areas can adjust the temperature to meet their actual needs. If your facility has many rooms or floors, multiple zones are recommended.

- Demand or CO2 Sensors: Most heating and cooling systems draw in ventilation air by assumed occupancy, however modern technology has sidestepped this by designing systems that actually can regulate the air quality of your facility by measuring the amount of CO2 present. The result is more energy-efficient operation and better air-quality.

Maintenance

Just like your automobile, your facility's heating and cooling systems need maintenance to operate efficiently. To improve efficiency and help ensure reliability and long life, consider the following tips.

- Engage a qualified HVAC firm in a maintenance contract with seasonal tune-ups. During these tune-ups, a technician should check combustion efficiency, refrigerant charge, and belt tension as applicable.

- Replace air filters regularly. Accumulated dirt and dust make your fans work harder. Clean or replace filters as recommended by your system's manufacturer.

- Clean the evaporator and condenser coils on your heat pump, air-conditioner, or chiller. Dirty coils inhibit heat transfer; by keeping them clean, you save energy.

- Inspect ducts and piping for leakage or damaged insulation. Leaky ductwork is one of the biggest contributors to cooling loss in buildings. Apply duct sealer, tape, and insulation as needed.

- Repair old valves and steam traps. These can waste hundreds of dollars and are low cost parts.

Energy Efficient Upgrades : Office Equipment and Appliances

When facility operators think of energy consumption, they naturally focus on building operations (such as lighting and air-conditioning) and its shell components, but not necessarily on the energy consuming office equipment and appliances contained within.

Office Equipment

As the nation transitions to a more service focused economy, a large portion of which are small businesses, the amount of energy consuming office equipment will also increase. Inefficient office equipment not only draws power, but also emits heat that can contribute to higher cooling bills. Fortunately, to address this issue there are a variety of ENERGY STAR qualified products that can help you save money and energy. If you are replacing or purchasing equipment such as computers, monitors, and copiers always consider ENERGY STAR qualified products.

Other office equipment savings opportunities include:

Did You Know?

Liquid Crystal Display (LCD) monitors use less than 1/3 of the energy of conventional Cathode Ray Tube (CRT) monitors.

- Turn office equipment off at night.

- Check to see if your computer already has power management software installed. If so, activate it.

- Print double sided per page; much more energy is used in the manufacturing and distributing of paper than the actual printing at your office.

Energy Efficient Upgrades : Refrigeration

Refrigeration equipment for businesses such as grocery stores, convenience stores, and restaurants typically account for 25% to 60% of electricity consumption. Fortunately, there have been many advances in commercial refrigeration technology - many of which are extremely cost effective with improved product quality.

Your facility's size and type, and the needs of your business may determine the type of refrigeration system used.

Central refrigeration systems consist of refrigerated spaces connected to a remote condenser. These systems have the advantage of emitting waste heat outside of the conditioned space through the condenser.

Stand-alone refrigeration systems, often called merchandisers, usually have the case, evaporator and condenser packaged in a single unit, similar to your home refrigerator. These stand-alone units are commonly used in smaller facilities where a central refrigeration system is not justified.

There are many other efficiency opportunities in refrigeration. When working with a contractor or service provider, ask them to review and specify additional efficiency measures, such as:

Did You Know?

Technology options can save considerably on electricity used for refrigeration.

Save:

- 10% with energy-efficient case lighting

- 3% to 10% with floating head pressure controls

- 5% to 13% with energy-efficient fan motors

- 1% to 6% with defrost controls

- 3% to 9% with evaporative condensers

- ENERGY STAR qualified commercial solid door refrigerators and freezers

- Premium insulation packages where available for walk-in coolers.

- National Electrical Manufacturers Association (NEMA) premium motors and/or variable speed drives on evaporator and condenser fans.

- Oversized condensers to supercool refrigerant.

- Humidistat controlled anti-sweat heaters, instead of timers, for large display systems.

- Evaporative condensers.

- Defrost controls, instead of timers, that measure frost accumulation and humidity.

- Floating head pressure systems and/or liquid pressure amplifier pumps.

- Efficient T8, T5, or compact fluorescent lighting with electronic ballasts.

- Glass door cases (instead of open door cases).

- Heat recovery from compressors and condensers to provide hot water.

- Automatic door closers (with appropriate interior safety releases).

Maintenance Tips

- Engage a qualified heating, cooling, and ventilation (HVAC) contractor in a maintenance contract with seasonal tune-ups. During these tune-ups, a technician should check combustion efficiency, refrigerant level, and belt tension as applicable.

- Properly load the unit. Overloaded refrigeration units result in disrupted airflow while under loaded units are using more energy than needed.

- Clean cooling coils regularly to ensure proper airflow and heat transfer.

- Whenever considering any modification to an existing refrigeration system that involves changing refrigerants, consult your refrigehttp://www.business.gov/guides/environment/energy-efficiency/upgrades/food-service-equipment.htmlration professional.